Product Details

- Product Description

-

Maybe you can call13412320139, we provide you with a detailed dispensing program!

Applicable fluid:

- syringe packaging glue:Can be directly placed on the 331 automatic dispensing machine direct dispensing, such as: 30ML, 50ML, 300ML and so on.

- bulk barrel packaging glue:It needs to be used with a pressure barrel. Pour the glue into the pressure barrel, and the air pressure presses the glue out to the automatic dispensing machine for dispensing.

- hot melt adhesive glue:30ML hot melt adhesive, 3M-2665, Loctite 3541/3542, etc., can directly use our company's 820 heating dispensing controller to directly fix the glue on the 331 automatic dispensing machine for heating dispensing. Hot melt glue such as glue particles, glue strips, glue sticks and other types need to be equipped with an external large-scale hot melt glue system RA1 universal hot melt glue machine to melt glue, and the 331 glue dispenser is responsible for the glue dispensing track.

- Multi-head, multi-color drop glue dispensing:The automatic dispensing machine 331 can be equipped with multiple dispensing heads, which can either discharge glue from multiple heads at the same time or each dispensing head can discharge glue separately.

Common applications are:

The automatic dispensing machine is 331 a universal three-axis automatic dispensing machine, which is basically applicable as long as the size of the dispensing product is within 300*300*100mm, including dam enclosure and filling, dotting, forming, drawing, bottom filling, etc.

Product basic parameters:

Model:

300

dispensing range X/Y/Z(mm):

300/300/100

Maximum load Y-AXIS / Z-AXIS:

10kg/5kg

Movement speed (mm/sec):

500 / 350

Decomposition capacity:

0.01 mm/Axis

Repeat accuracy:

/- 0.01 mm/ Axis

Program recording mode:

At least 100, 5000 points per group (can support uploading computers)

Display mode:

LCD teaching box

Motor system:

Japanese micro-stepping precision motor

Mode of operation:

PTP & CP

Transmission mode:

Synchronous belt

Motion tween function:

3 axis (any route can be used in 3D stereo space)

Edit mode:

Teaching Box

I/0 signal:

3Inputs / 4 Outputs

External control interface:

RS232

Input power:

Full voltage AC110V ~ 220V (internal switch conversion)

Working environment temperature:

5 -40 ℃

Working environment humidity:

20 -90%

External dimensions (WxDxH mm):

480 × 526.5 × 591

Body weight (kg):

47 kg

- syringe packaging glue:Can be directly placed on the 331 automatic dispensing machine direct dispensing, such as: 30ML, 50ML, 300ML and so on.

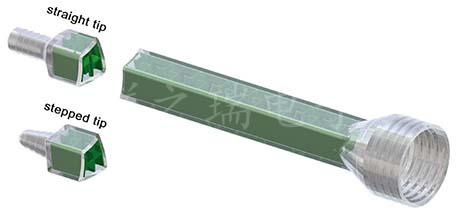

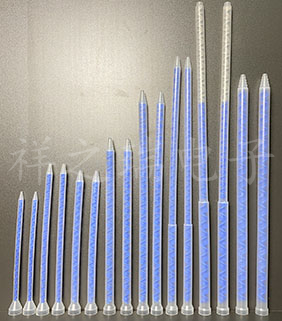

keyword:Mixing tube

Previous Page

online message