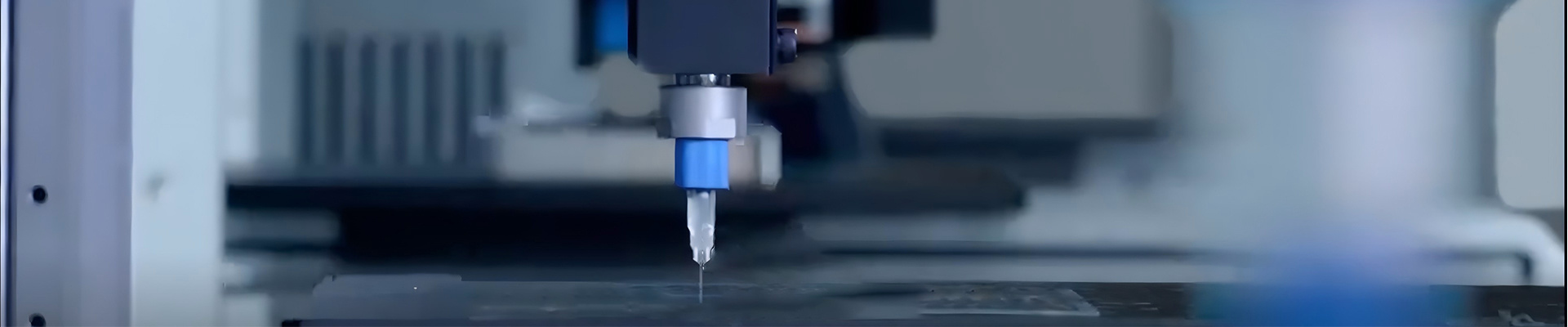

Automatic soldering machine

Category:

Product Details

- Product Description

-

An automatic soldering machine is an automated soldering equipment that works by heating the solder wire, melting it into a liquid state, and then precisely spraying the molten solder onto the electronic components that need to be soldered. It is mainly divided into two types: semi-automatic soldering machine and fully automatic soldering machine. A semi-automatic soldering machine requires manual assistance to complete part of the soldering work, while a fully automatic soldering machine can completely automatically complete the soldering process. If you need to know more details, please call us to contact us, and our professional engineers will tailor a dispensing solution for you!

Automatic soldering machine

Application range:

Used for soldering various electronic components, such as capacitors, resistors, pin headers, cables, RJ45, LEDs, remote control boards, etc. The dual-station soldering machine makes it easier to change fixtures, saving time and improving efficiency.

Application fields:

Communication industry, optoelectronics industry, home appliance industry, automotive industry, toy industry, etc.

★Working characteristics:

- The X, Y, and Z axes achieve positioning at any point in three-dimensional space, and the R axis (rotation axis) can achieve any angle to avoid components around the solder joint.

2. Imported high-power heating cores are used to achieve constant temperature soldering, increase production capacity, and improve soldering quality.

3. Input setting parameters are safer, faster, and more convenient. The machine replaces manual labor more efficiently, with automatic pneumatic cleaning of the soldering iron.

4. The solder volume of a single solder joint is controlled by setting the solder dispensing speed and time through the program, and the solder volume of each solder joint can be controlled individually to ensure the consistency of the solder quality and the welding quality.

★Application range:

Used for soldering various electronic components, such as capacitors, resistors, pin headers, cables, RJ45, LEDs, remote control boards, etc. The dual-station soldering machine makes it easier to change fixtures, saving time and improving efficiency. Communication industry: Apple product data cables, HDMI, RJ45, FPC, high-frequency heads, etc.; Optoelectronics industry: LED displays, LED strips, LED rectifiers, LED spherical lamps, LED beads, etc.; Home appliance industry: air conditioner remote controls, air conditioner control boards, computer speakers, TV switch connectors, etc.; Automotive industry: ignition switches, automotive fuel level sensors, navigation systems, motorcycle flashlights, etc.; Toy industry: toy handle connectors, circuit boards, etc., are suitable for soldering with this equipment.

- The X, Y, and Z axes achieve positioning at any point in three-dimensional space, and the R axis (rotation axis) can achieve any angle to avoid components around the solder joint.

Previous Page

Next Page

Online Message